Winter Workshop Setup: Must-Have Tools for Cold Weather Projects

When the temperature drops and daylight hours shrink, your workshop faces unique challenges. But with the right preparation, winter can become your most productive DIY season, free from the distractions of garden work and outdoor activities.

Winter workshops present both opportunities and obstacles for UK DIYers. The shorter days mean you’ll rely heavily on artificial lighting, while cold temperatures can affect everything from battery performance to wood movement. However, this season also offers uninterrupted time for indoor projects, furniture making, and preparing for spring renovations.

The key to a successful winter workshop lies in addressing three fundamental challenges: maintaining comfortable working temperatures, ensuring adequate lighting for precision work, and adapting your tool selection for cold-weather performance. Many DIYers abandon their workshops during winter months, but those who prepare properly often find it their most creative and productive period.

Conquering the Cold: Heating Solutions That Work

The most immediate challenge in any UK winter workshop is maintaining a temperature that allows comfortable, precise work. Cold fingers struggle with fine adjustments, and many materials become brittle or difficult to work with below certain temperatures. The solution isn’t necessarily heating your entire workshop to living room standards, but rather creating zones of warmth where you need them most.

Electric fan heaters offer the quickest warm-up times and can be positioned to heat specific work areas rather than the entire space. Look for models with thermostatic controls and safety cut-offs, particularly important in dusty workshop environments. A 2kW unit will typically warm a single-car garage workshop adequately for most work, though you’ll want to consider running costs during extended use.

For larger workshops or those used regularly throughout winter, infrared heaters provide more efficient long-term heating. These warm objects and people directly rather than heating air, making them ideal for draughty spaces. Wall-mounted infrared panels can be positioned above workbenches to create comfortable working zones without the energy costs of heating unused areas.

Oil-filled radiators work well for maintaining background temperatures overnight, preventing tools from becoming uncomfortably cold and reducing condensation issues. While slower to heat up than fan heaters, they provide steady, consistent warmth and are safer to leave unattended.

The key consideration for any workshop heating is moisture management. Rapid temperature changes can cause condensation on tools and metal surfaces, leading to rust problems. Gradual heating combined with adequate ventilation helps maintain the right balance between comfort and tool preservation.

Lighting the Way: Illumination for Precision Work

Winter’s shortened daylight hours make artificial lighting crucial for workshop productivity. Poor lighting leads to eye strain, inaccurate cuts, and increased accident risk. The goal is creating shadow-free illumination that allows you to see fine details clearly, whether you’re marking measurements or finishing delicate work.

LED strip lighting has revolutionised workshop illumination, offering bright, even light distribution at a fraction of traditional fluorescent running costs. Installing strips both overhead and under wall-mounted cabinets eliminates shadows that single-point lighting creates. Choose daylight-balanced LEDs around 5000K colour temperature for the most natural light that won’t distort wood grain colours or paint finishes.

Task lighting becomes even more critical during winter months when you’re working entirely under artificial illumination. Adjustable LED desk lamps positioned at your primary workstations provide focused light exactly where needed. Look for models with dimming controls and multiple colour temperatures, allowing you to adjust lighting intensity for different tasks.

For detailed work like electronics or fine joinery, magnifying lamps combine illumination with optical enhancement. These prove invaluable for aging eyes or intricate work that demands precision. Modern LED magnifying lamps run cool and provide excellent light quality without the heat buildup of older halogen models.

Consider the psychological impact of lighting as well. Bright, well-distributed lighting helps combat the winter blues that can affect motivation during darker months. A well-lit workshop feels more inviting and encourages longer, more productive work sessions.

Tool Performance in Cold Conditions

Cold weather significantly impacts tool performance, particularly cordless tools that rely on battery chemistry. Lithium-ion batteries lose capacity as temperatures drop, with performance declining noticeably below 10°C and becoming severely compromised near freezing. Understanding these limitations helps you plan projects and manage tool performance during winter months.

Battery-powered tools benefit from being stored in heated areas when not in use. Bringing batteries indoors overnight and allowing them to warm to room temperature before use can dramatically improve runtime and power delivery. Some professionals keep spare batteries in heated toolboxes or even inside pockets to maintain optimal temperature.

Corded tools generally perform more consistently in cold conditions, making winter an ideal time to rely on mains-powered equipment for demanding tasks. However, extension leads become more critical, and cold cables can become stiff and difficult to manage. Investing in cold-weather rated extension leads with flexible outer jackets pays dividends during winter use.

Metal tools require particular attention in cold workshops. Condensation forms when cold tools are brought into heated spaces, potentially causing rust on precision surfaces. Wiping tools dry and applying light oil films helps protect against moisture damage. Tool storage in heated areas or with desiccant packs reduces condensation problems.

Hand tools can become uncomfortably cold to handle, affecting grip and dexterity. Thin work gloves designed for precision tasks allow tool use while providing some insulation. Alternatively, storing frequently used hand tools near heat sources keeps them comfortable to handle.

Winter-Perfect Projects and Materials

Winter workshops excel at certain types of projects while presenting challenges for others. Understanding which materials and techniques work best in cold conditions helps you plan productive winter sessions and avoid frustrating setbacks.

Woodworking becomes particularly rewarding during winter months when outdoor projects are impractical. However, wood movement increases significantly with temperature and humidity changes. Timber stored in cold conditions needs time to acclimatise to workshop temperatures before machining. This seasonal movement means joints cut in winter may loosen during summer expansion, requiring different approaches to traditional joinery.

Finishing work requires special consideration in cold workshops. Most paints, stains, and clear finishes have minimum application temperatures, typically around 10°C for water-based products and 5°C for solvent-based finishes. Cold temperatures slow curing times dramatically and can cause finish defects. Planning finishing work for warmer days or investing in workshop heating during application becomes essential.

Adhesives also perform differently in cold conditions. PVA glues slow their cure times significantly, while some construction adhesives may not cure properly below certain temperatures. Epoxy adhesives generally handle cold better but still require longer cure times. Reading manufacturer specifications for temperature requirements prevents project failures.

Metalworking can actually benefit from cold conditions, as metal cutting generates less heat buildup and tools stay sharper longer. However, cutting fluids may thicken, and some metals become more brittle. Cast iron, in particular, requires careful handling in very cold conditions to prevent cracking.

Electronics projects work well in winter workshops, as components and circuit boards are less affected by cold than by heat. However, static electricity increases in dry winter air, requiring additional ESD precautions when handling sensitive components.

Storage Solutions for Harsh Conditions

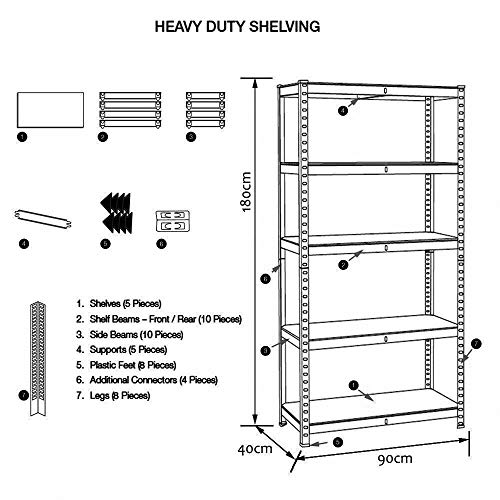

Proper storage becomes critical during winter months when temperature swings and humidity changes threaten tool condition and material stability. The challenge lies in protecting valuable equipment while maintaining easy access for ongoing projects.

Precision tools like measuring equipment, marking gauges, and cutting tools benefit from climate-controlled storage. A simple heated cabinet or even a large toolbox with a small heater can maintain stable conditions for your most valuable tools. This prevents the thermal cycling that causes precision surfaces to develop rust and maintains calibration accuracy.

Material storage requires particular attention during winter. Lumber needs protection from both moisture and rapid temperature changes that cause warping and splitting. Storing wood in heated areas isn’t always practical, but ensuring good air circulation and protection from direct moisture prevents most problems. Sheet materials like plywood and MDF are particularly susceptible to moisture absorption and should be stored vertically with air gaps between sheets.

Fasteners and small hardware benefit from organised storage in sealed containers with moisture-absorbing packets. Nothing ruins a project faster than discovering your screws have developed surface rust or your drill bits have dulled from corrosion. Clear storage boxes allow easy identification while providing protection from workshop humidity.

Chemical storage becomes more complex in winter workshops where temperatures may fluctuate significantly. Many finishes, adhesives, and solvents have specific storage temperature requirements. Some may separate or become unusable if allowed to freeze, while others become dangerously volatile if stored too warm.

Safety Considerations for Winter Workshops

Working in winter conditions introduces unique safety challenges that require additional precautions beyond normal workshop safety protocols. Cold-related issues can develop gradually, making them easy to overlook until they become serious problems.

Heating equipment introduces fire and carbon monoxide risks that don’t exist in unheated workshops. Proper ventilation becomes crucial when using any combustion heating, while electrical heating requires attention to circuit loading and extension lead ratings. Dust and sawdust accumulation near heat sources creates particular fire hazards that need regular attention.

Reduced dexterity from cold exposure affects tool control and increases accident risk. Recognising when fingers become too cold for safe tool operation prevents injuries from slipped cuts or dropped tools. Taking regular warming breaks maintains both safety and work quality.

Condensation on tool surfaces creates slip hazards and can make handles difficult to grip securely. Wiping tools dry before use and maintaining adequate ventilation reduces these risks. Non-slip mats become more important when workshop floors may be damp from condensation or tracked-in moisture.

Emergency preparedness takes on added importance when working in cold conditions. Ensuring mobile phone access, having first aid supplies readily available, and informing others of your workshop schedule becomes more critical when hypothermia could complicate injury response.

Maximising Productivity During Short Days

The limited daylight hours of UK winters require strategic planning to maintain productive workshop sessions. Understanding your energy patterns and planning projects accordingly helps make the most of available time.

Morning sessions often prove most productive when you’re fresh and workshop temperatures are at their most stable. Pre-heating your workshop before starting work eliminates the warm-up period and allows immediate productivity. Timer-controlled heating can warm your space before you arrive, maximising actual working time.

Project planning becomes more important when working time is limited. Breaking larger projects into discrete sessions that can be completed in available time prevents frustrating interruptions at critical stages. Having multiple projects at different stages allows flexibility to match tasks to available time and energy levels.

Preparation work during shorter sessions sets up success for longer weekend workshops. Dimensioning lumber, organising materials, and setting up machinery during brief evening sessions maximises productivity when longer working periods become available.

Winter workshops offer unique opportunities for focused, uninterrupted project work, but success requires thoughtful preparation and adaptation to seasonal challenges. By addressing heating, lighting, and tool performance issues proactively, you can maintain productivity throughout the coldest months while protecting your valuable equipment.

The key lies in understanding that winter workshop work is different, not inferior, to warm-weather sessions. Embracing projects and techniques that suit cold conditions while properly preparing your space and tools creates a workshop environment that remains productive year-round.

With proper setup, many DIYers find winter becomes their most creative and accomplished season, free from the outdoor distractions of warmer months and blessed with long, uninterrupted sessions perfect for complex projects and skill development.

Transform your cold workshop into a year-round productive space. Browse our complete range of workshop equipment and tool storage solutions to create the perfect winter workshop setup. From heating solutions to precision lighting, we stock everything you need for comfortable, productive cold-weather DIY work.